Multiple Methods Used to Increase Speed in Your Electric Motor

Multiple Methods Used to Increase Speed in Your Electric Motor

Cutting costs often leads to undeserving the needs of an application to where components are operating continuously at peak values rather than sizing components to a more median and safer range indicated by technical data available. For all components, particularly stepper motors, this cost-saving trend can cause stress on components leading to early failures of the applications they are used in. One of the ways to build a system that performs well, even to tighter specifications and higher standards of operation, is to understand your options.

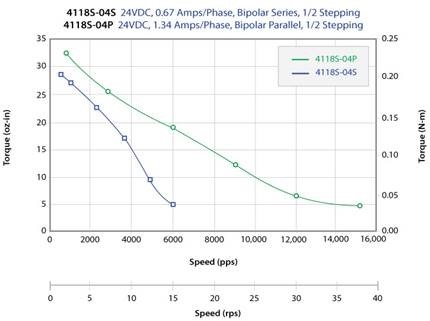

According to Seth Hutchinson, Applications Engineer at Lin Engineering, “Before even considering speed, your first consideration should be how much torque will be required to move your load.” He goes on to explain how knowing the amount of torque you’ll require can lead you to the manufacturer’s technology pages where you will find standard torque/speed curves for each stepper motor. This information is critical to determine the maximum allowable speed you’ll get from a particular motor (see Figure 1).

Notice the green line on the graph in Figure 1. It is clear that when the motor is rotating at 15 revolutions per second (RPS), the maximum torque will be in the range of 19 oz-in. As long as your design doesn’t require a faster speed than that shown in the graph your application will perform properly between 0 and 15 RPS.

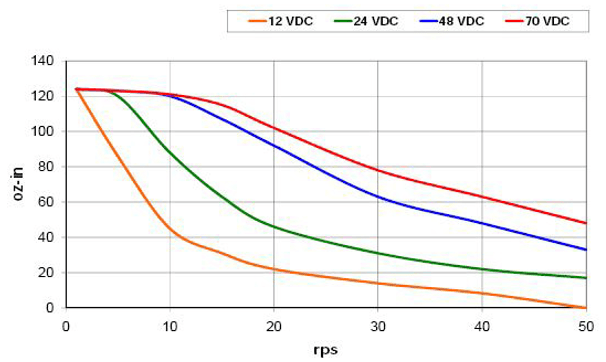

Things can change, though, when your supplied operating voltage changes. So, you’ll want to determine what operating voltage will be supplied to the system. Once again, if you look at the technical data provided by your manufacturer you may find something like the graph in Figure 2. Note that, in this graph, as you increase your supply voltage to the motor that the maximum torque is achievable at a higher speed. Also, note that the maximum initial torque does not change under these conditions—as though the curve has merely been shifted to the right.

Increasing the voltage to the motor is not the same as increasing the current to the motor. If you increase the motor current past the recommended rated value, it will quickly destroy the motor. Applying a higher voltage will not damage the motor. Yet an increased voltage will cause more heat to be generated, which means your application will need to provide better ventilation or some other type of heat dissipation in order to assure long operation lifetimes.

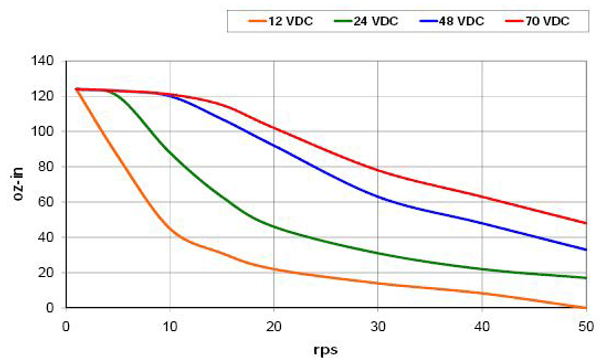

Changes in the torque and speed slope can occur through adjusting the windings, too. For example, an increase in the number of windings inside the motor will allow for greater torque specifications but result in only small speed increases. Fewer windings, on the other hand, will increase the speed range but reduce the lower speed torque values (see Figure 3).

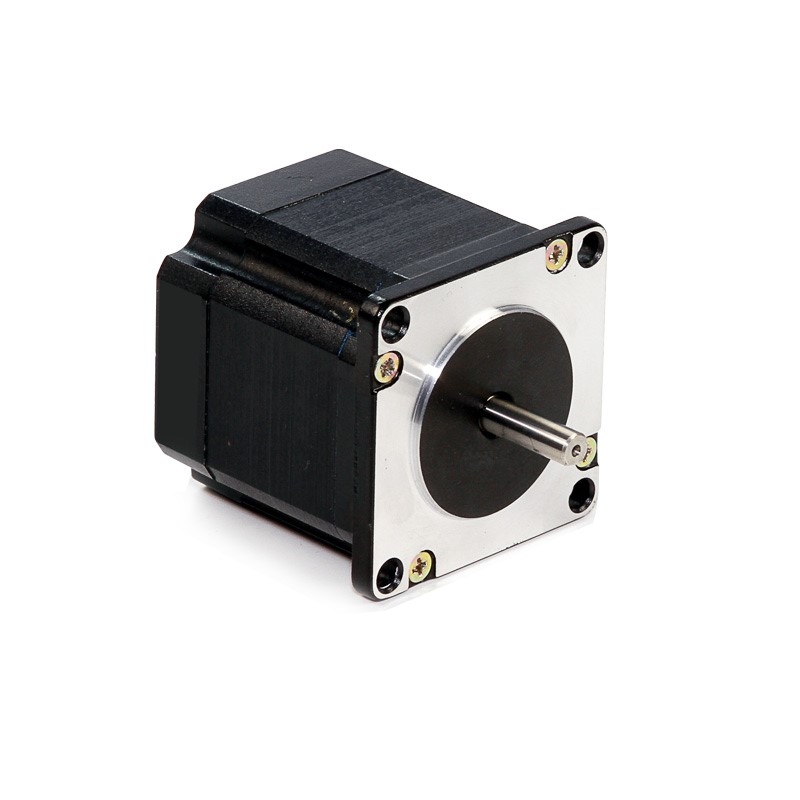

Motor frame sizes make a difference because the design has more space to work in. Simply put, if you compare a NEMA 17 and NEMA 23 motor (see Figure 4) you’ll find that the larger motor is capable of higher speeds as well as higher torques at those speeds. This is because of values of scale. Since the motors shown are stepper motors it is important to note that they are known to run hot because the coils are always energized—even when the motor is not moving.

Even though stepper motors are rated for 80 C externally and 130 C internally if the motors are to be installed and operated in temperatures that are higher the internal insulation can be changed allowing temperatures to reach as much as 180 C. Once again, it is important to be sure you’re not overdriving the motor with a higher current than it is rated for or the motor can break down.

Because accuracy is important in any design, remember that as long as you are running your stepper motor under its maximum torque values and its rated speed has not surpassed, the motor will not experience any changes in accuracy or repeatability.

In conclusion, the rule of thumb is that as the speed of the motor increases the dynamic torque will decrease—however, this change is not a linear slope. When designing stepper motors into your application always be sure to review the manufacturer’s torque/speed curves to be sure they fit your needs. Custom and semi-custom motors can be created by companies like Lin Engineering so that they fit your application perfectly.

For more information:

News

Continue Reading

Get to Know Lin Engineering: Motor Specialist in Motion

Lin Engineering started in a garage—I’m sure you’ve heard that before. What may be more interesting is, unlike other companies that started in a garage, Ted Lin wasn’t creating a product, per se. He was adjusting a product to specifically perform in a certain way for a particular application. He was an innovator.

Rapid DC Motor Manufacturing For Fight Against COVID-19

With the COVID-19 outbreak, the demand for medical equipment has been quickly increasing. A lot of these devices depend on their precise motors to operate. In order to support the ongoing efforts to combat COVID-19, we are prioritizing the production and supply of our motors to support companies producing medical devices critical to the treatment of COVID-19 patients.