Vacuum Rated DC Motors

Lin Engineering's vacuum-rated stepper motors and BLDC motors are engineered for operation is high vacuum (HV) environment, emphasizing not only high power density but also exceptional durability under extreme conditions. Additionally, motors are designed to withstand severe temperature variations and offer vibration and shock resilience. Many options are standardized and available as COTS (commercial off the shelf).

- Vacuum (HV) operation up to 10⁻⁷ torr

- High/Low temp operation from -50°C to +100°C (optional -70°C to 130°C)

- COTS standardized motors

- Vibration and shock resistant

- Low outgassing material construction (%TML < 1%)

- Lightweight/high power density construction

- Many customizations available

- USA based production and assembly

- Full USA based engineering support

Choose Your Motor

Our selection includes Stepper Motors, Standard Framed BLDC Motors, and Frameless BLDC Motors, all designed to perform reliably in vacuum environments. These motors are ideal for industries that require precision and durability in challenging conditions.

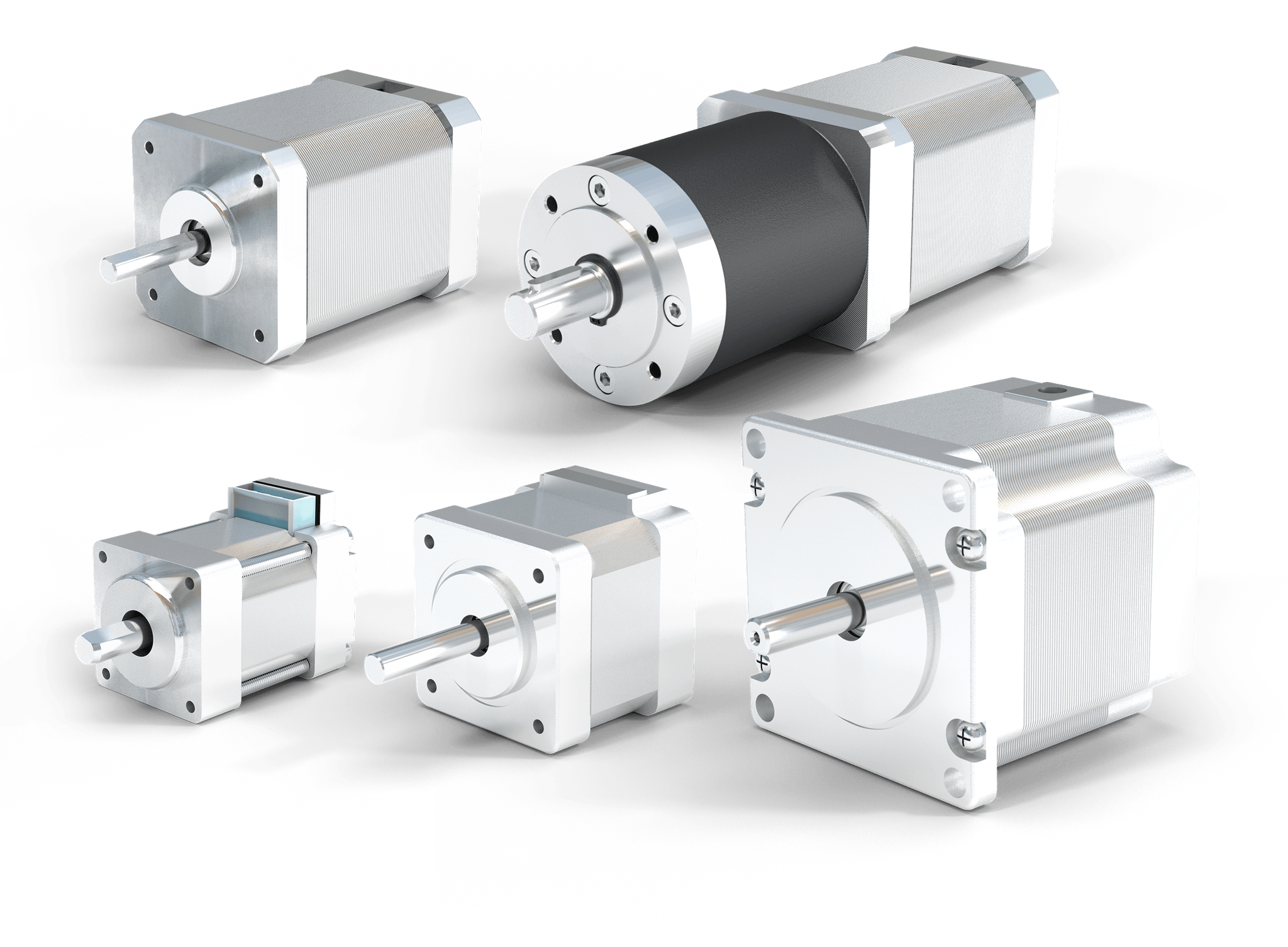

Hybrid Stepper Motors

Hybrid stepper motors offer significant advantages for space applications, blending cost-effectiveness with operational simplicity. Stepper motors operate in open-loop systems without the need for complex feedback mechanisms. This simplifies the design and reduces the overall system cost, while ensuring precise control and reliability in the vacuum of space. Tailored for aerospace requirements, our motors provide a straightforward, economical solution for achieving precise motion control in the challenging environment of space.

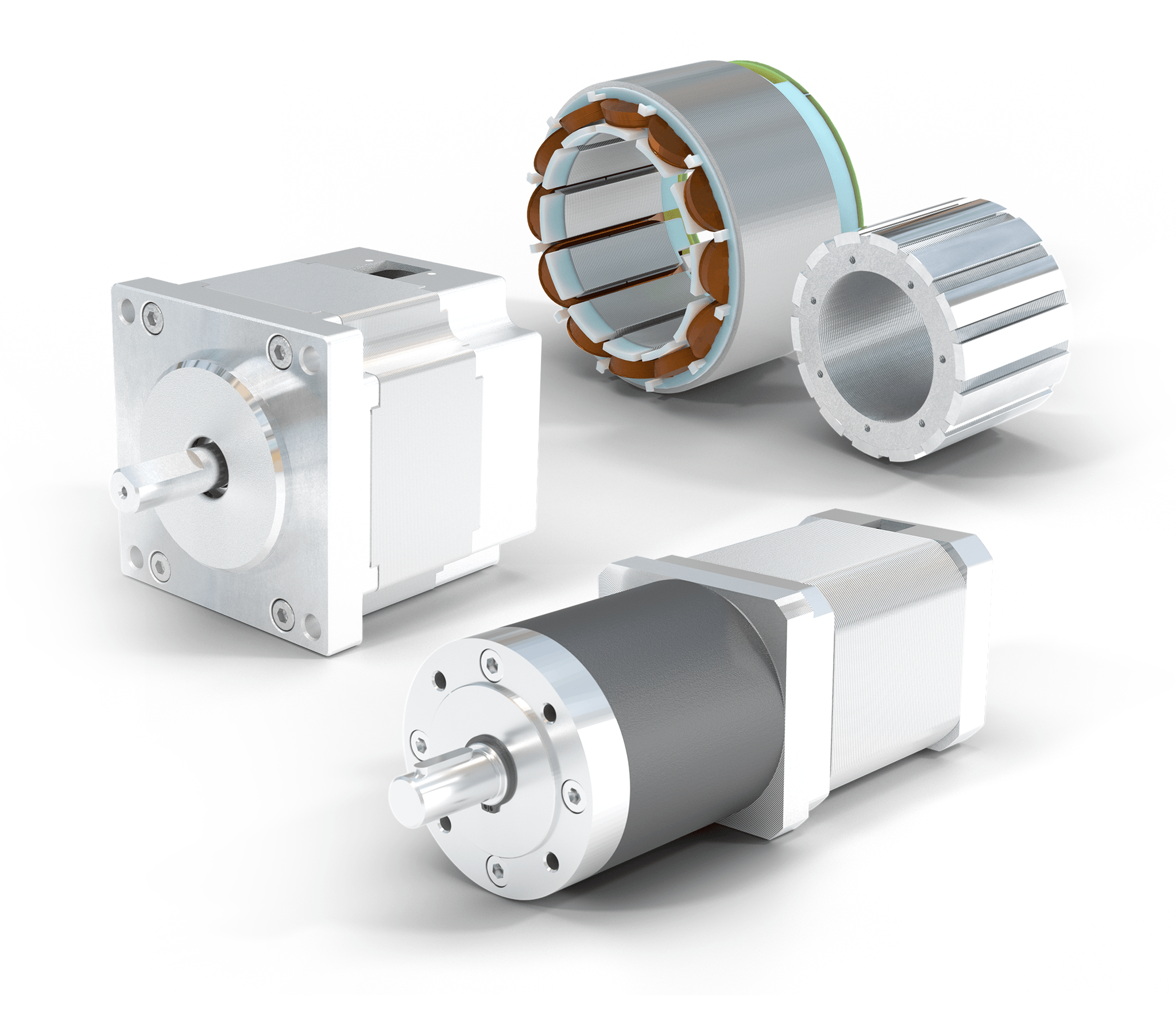

Geared Motors

Vacuum rated gearboxes are available upon request. Please contact sales support for more information.

| Specification | VX208 Series | V211 Series | V3518 Series | V4118 Series | V5718 Series |

|---|---|---|---|---|---|

| Frame Size | 20.3 mm (NEMA 08) | 28.2 mm (NEMA 11) | 35.3 mm (NEMA 14) | 42.4 mm (NEMA 17) | 57.2 mm (NEMA 23) |

| Step Angle | 1.8° | 1.8° | 1.8° | 1.8° | 1.8° |

| Length | 29.5 to 46.5 mm | 32 to 51.1 mm | 34 to 55.5 mm | 34 to 59.44 mm | 44.2 to 78.7 mm |

| Holding Torque | 0.03 to 0.058 Nm | 0.06 to 0.12 Nm | 0.14 to 0.4 Nm | 0.3 to 0.88 Nm | 0.71 to 2.08 Nm |

| Rated Current | 0.5 to 0.9 A | 0.67 to 1.3 A | 0.8 to 2 A | 0.67 to 2 A | 1.4 to 4.2 A |

| Rated Voltage | 24 VDC | 24 VDC | 24 VDC | 24 VDC | 24 VDC |

| Weight | 40 to 80 g | 109 to 200 g | 159 to 240 g | 182 to 409 g | 477 to 1066 g |

| Coming Soon Request Quote for VX208 | View V211 Spec Request Quote for V211 | View V3518 Spec Request Quote for V3518 | View V4118 Spec Request Quote for V4118 | View V5718 Spec Request Quote for V5718 |

BLDC Motors

Lin Engineering’s BLDC motors deliver smoother rotation, greater efficiency, and superior performance at high speeds, due to their use of electronic commutation. This design minimizes mechanical wear and reduces energy losses, making BLDC motors ideal for applications requiring continuous operation. Unlike steppers, which are optimized for precise positioning tasks, BLDC motors excel in high-speed, continuous-duty applications, generating less heat even during prolonged operation.

| Specification | VBL17 | VBL23 |

|---|---|---|

| Frame Size | 42 mm (NEMA 17) | 56 mm (NEMA 23) |

| Rated Torque | 0.072 to 0.215 Nm | 0.15 to 0.43 Nm |

| Rated Speed | 4000 RPM | 4000 RPM |

| Rated Current | 0.81 to 4.92 A | 1.6 to 6.9 A |

| Rated Voltage | 24 to 48 VDC | 24 to 48 VDC |

| Length | 47 to 101 mm | 55.5 to 121.5 mm |

| Weight | 320 to 830 g | 640 to 1700 g |

| Coming Soon Request Quote for VBL17 | Coming Soon Request Quote for VBL23 |

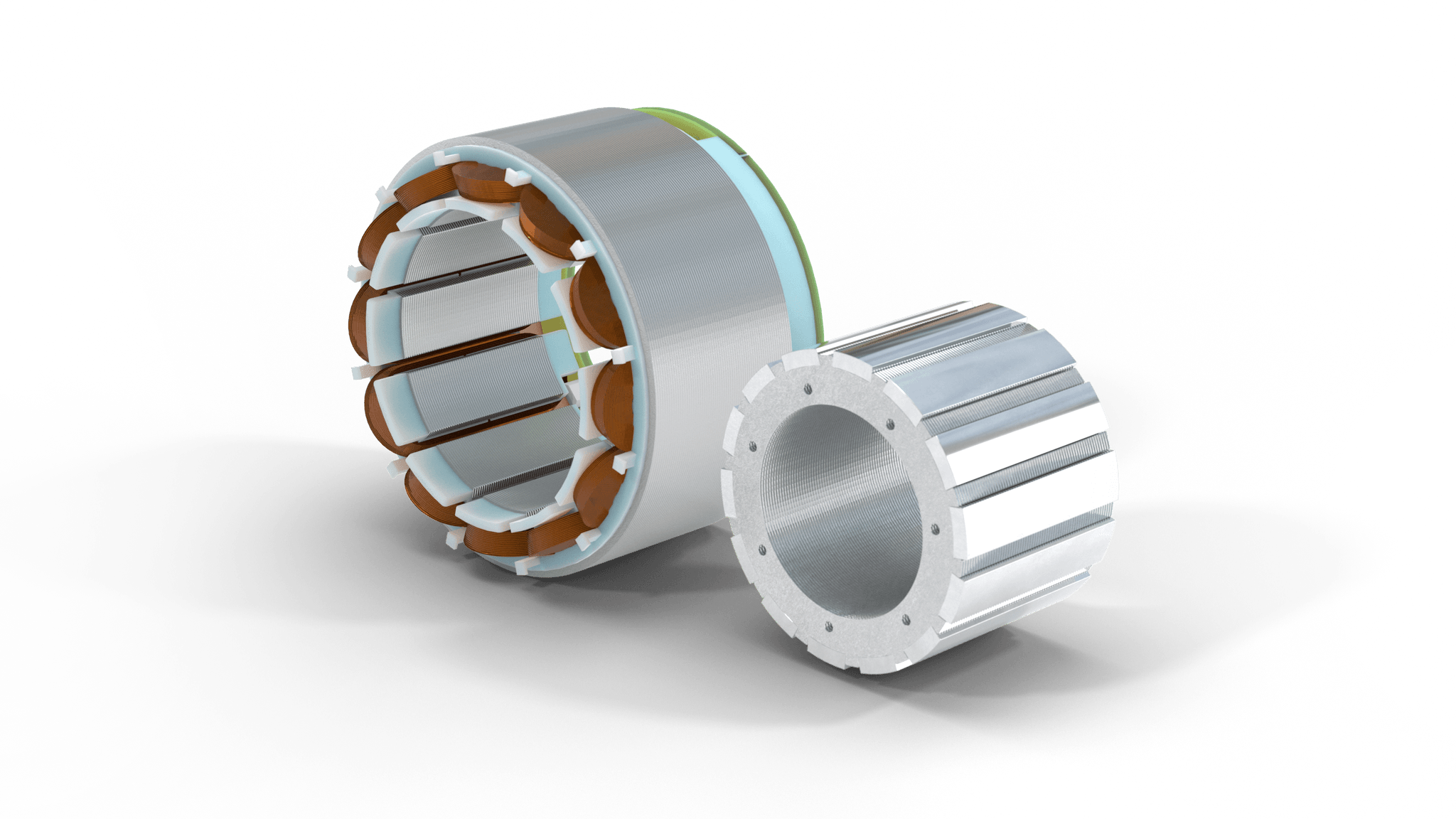

Frameless BLDC

Lin Engineering’s vacuum-rated frameless FlexCore and PowerCore motors are ideal for space-constrained applications, offering high power density and customizable designs to meet specific engineering needs. FlexCore motors provide balanced, high-value performance, while PowerCore motors deliver exceptional power density and efficiency, ensuring reliable motion control and innovation for demanding applications.

|  | |

|---|---|---|

| Frame Sizes | 40 to 137 mm | 50 to 115 mm |

| Stack Lengths | 7.1 to 25 mm | 8.2 to 26.3 mm |

| Cont. Torque | 0.23 to 5 Nm | 0.27 to 6.04 Nm |

| Peak Torque | 0.43 to 10 Nm | 0.59 to 17.46 Nm |

| Rated Speed | Up to 5000 RPM | Up to 4800 RPM |

| Rated Power | Up to 122 W | Up to 103 W |

| Rated Voltage | 18 to 120 VDC | 48 VDC |

| Rated Current | 1.26 to 5.2 A | 2.11 to 8.53 A |

| Motor Constant | 0.049 to 0.771 Nm/√W | 0.06 to 0.82 Nm/√W |

| View FlexCore MotorsRequest Quote for FlexCore Motors | Coming SoonRequest Quote for PowerCore Motors |

Built For Extreme Environments

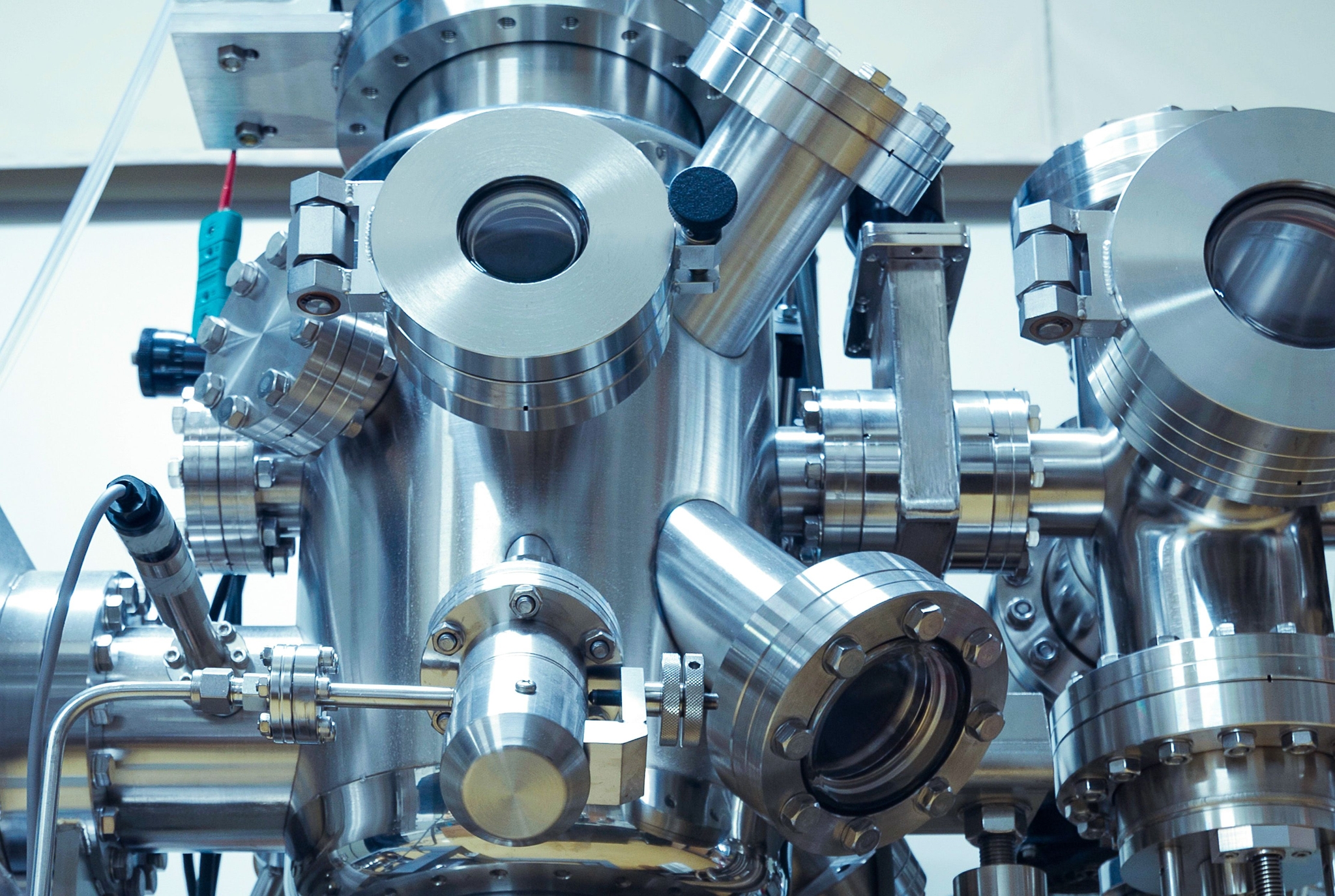

High Vacuum (HV) Operation

These motors are designed to function reliably at pressures as low as 10⁻⁷ torr, making them ideal for applications where maintaining a contamination-free environment is critical. Whether used in semiconductor processing, scientific research, or other vacuum-sensitive industries, our motors deliver precision, durability, and low heat generation.

Extreme Temperature Resilience

Motors are designed to operate reliably in a wide temperature range of -50°C to +100°C (optional -70°C to 130°C), making them suitable for applications that experience extreme environmental conditions. These motors are built to handle rapid temperature cycling ensuring consistent performance and longevity. For applications requiring even broader temperature tolerance, additional provisions can be implemented to further enhance both negative and positive temperature limits.

Shock/Vibration Resilience

Motors are built to withstand both high and low amplitude vibrations, ensuring structural integrity and reliable performance. Their robust design minimizes the risk of mechanical failure or degradation, making them ideal for applications that require consistent operation under varying vibration conditions.

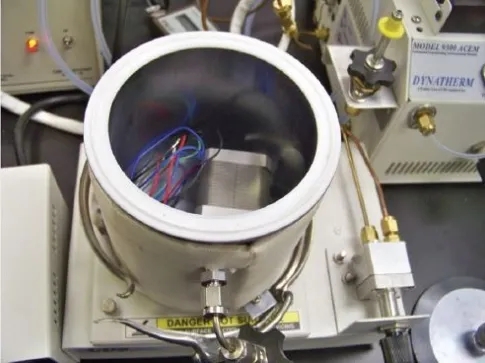

Low Outgassing Construction

Motors are constructed using low outgassing materials and are post-baked to ensure optimal performance in high vacuum environments. This process helps minimize the release of volatile substances, which is crucial for maintaining a clean vacuum environment. Our motors are designed to meet stringent requirements, with a CVCM (Collected Volatile Condensable Materials) value below 0.1%, ensuring minimal contamination and reliable performance in vacuum-sensitive applications.

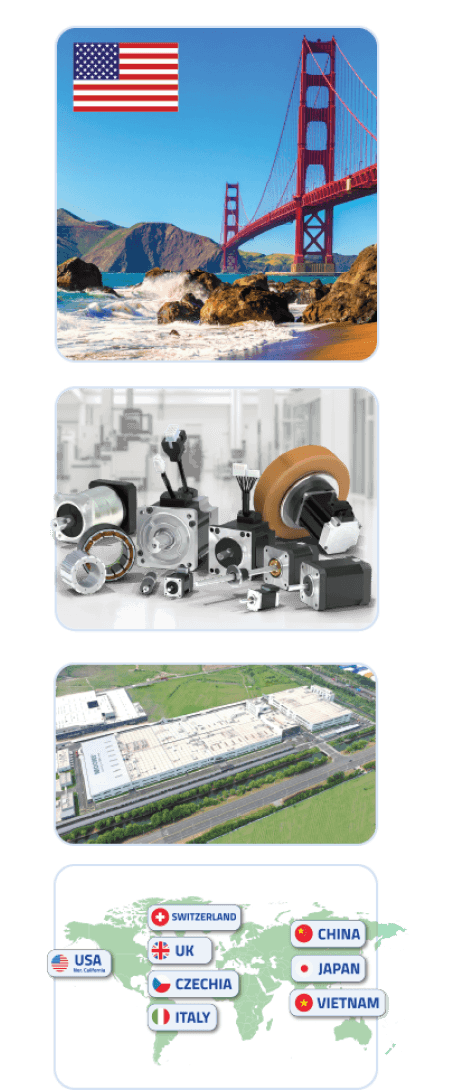

Why Choose Lin Engineering?

Choosing Lin Engineering as your supply chain partner means gaining access to a trusted leader in motion control with decades of expertise in designing and manufacturing high-performance motors. We offer tailored solutions, from prototype to high-volume production, ensuring that your motors are optimized for your specific application. Our commitment to quality, customization, and on-time delivery is unmatched, and our in-house engineering and support teams work closely with you to meet your technical and operational needs. With our ability to scale production and provide motors with precision performance, Lin Engineering ensures seamless integration into your supply chain for long-term success.

- USA-based Engineering and Manufacturing

- USA-based Engineering and Manufacturing

- Fast-track Prototyping

- Off-the-shelf motors and fast prototype turnaround

- Collaborative Engineering Support

- We can work closely with your team to create a customized solution for your specific application

- Engineered for Manufacturability

- Customized, plug-and-play motor solutions

- Sustainable Supply Chain

- Long-term motor manufacturing support throughout the lifecycle of your product

- Scalable Production

- From 10 motors to 10 million motors

- Vertically Integrated

- We manufacture our own components, ensuring supply chain stability and on-time delivery