Coreless Motors: An Innovative Solution for Precise and Efficient Motion Control

Coreless Motors

In an era where efficiency and precision take precedence, coreless motors are rising to the forefront of numerous industries, offering a host of benefits over traditional electric motors. These unique motors, which lack an iron core in their winding coils, have an innovative design with some superior features. Below we will unpack the mechanics of coreless motors, their distinctive advantages such as reduced weight, improved efficiency, and low noise, as well as their varied applications in fields ranging from robotics to aerospace. Whether you're designing a new medical device, seeking enhanced performance in existing applications, or grappling with space constraints, understanding the potential of coreless motors can be game-changing.

What are Coreless Motors?

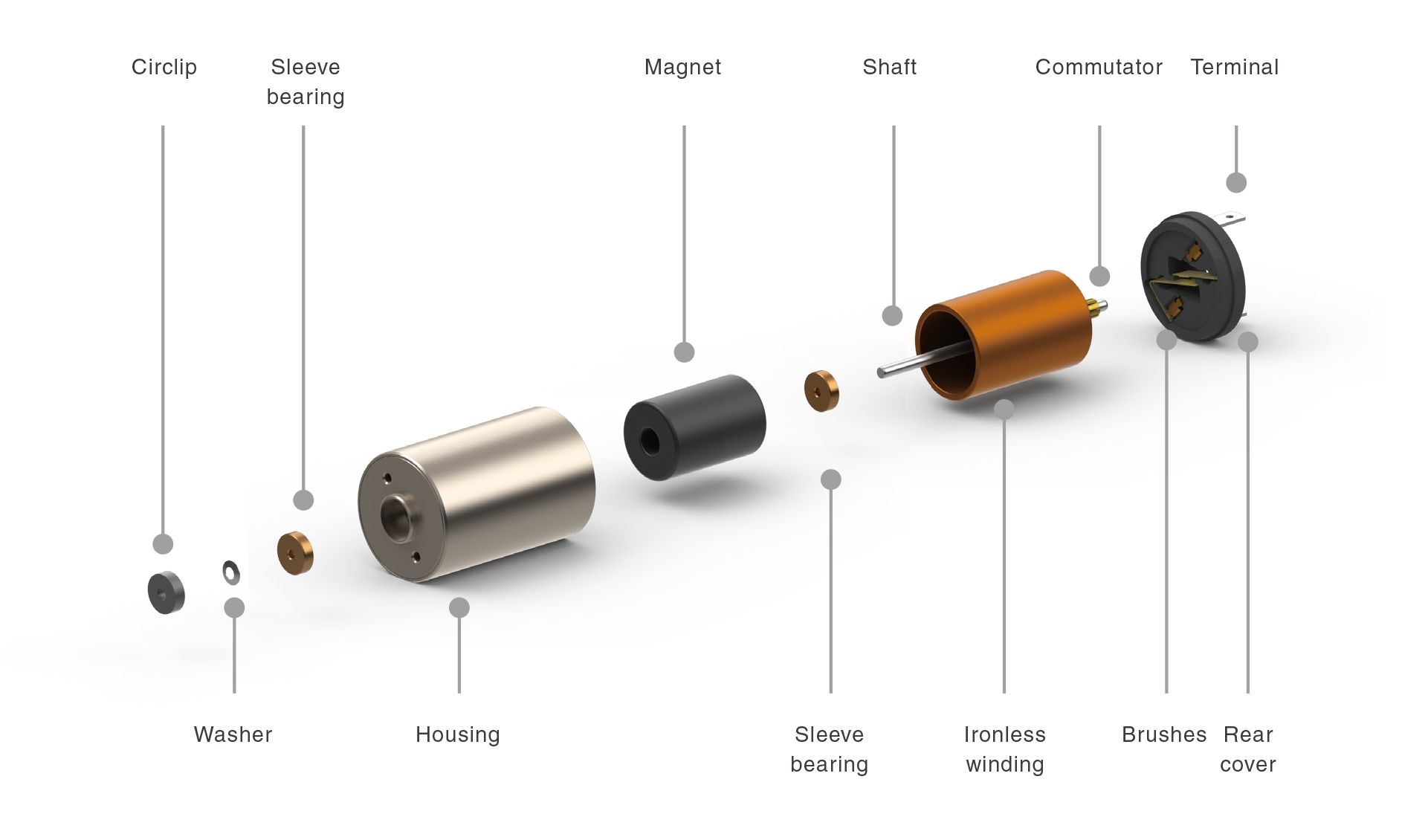

A coreless motor is a distinctive type of Direct Current (DC) Brushed electric motor, devoid of an iron core in its armature. Instead, the windings are compactly designed into a cylindrical form, creating a lightweight, low-inertia rotating component. This design fosters rapid response times during acceleration, enhancing the motor's operational efficiency. The skewed formation of the windings leads to a virtually cog-free motion, allowing precise control and smooth operation. From a financial standpoint, the coreless motor design is economical due to its inherent cost-effectiveness. The elimination of the requirement for supplementary driving electronics simplifies the design, leading to reductions in both the initial investment and ongoing maintenance expenses.

Advantages of Coreless Motors

- High Acceleration: With the absence of an iron core, coreless motors exhibit low rotational inertia, thereby enabling quicker acceleration and deceleration. This feature makes them an excellent choice for applications requiring swift and precise movement changes.

- Precise & Smooth Motion: The complete absence of cogging in coreless motors leads to enhanced precision in motion, especially at low speeds. This feature is particularly advantageous in applications where precise movements are essential, like in printing equipment or delicate medical procedures.

- Low Noise: Due to the lack of cogging and reduction of vibration, coreless motors are quieter than a typical motor.

- Improved Efficiency: Due to the design of a coreless motor, they draw very little current during idle or no-load times, making them a good choice for battery-operated devices or applications with reduced energy consumption.

- Reduced Weight & Size: The absence of a core in coreless motors reduces the overall weight and size of the motor, making it more suitable for applications where space and weight constraints are a concern.

- High Power Density: Coreless motors offer higher power density compared to traditional motors of similar size, allowing for more power in a smaller package.

Applications of Coreless Motors

Coreless motors are commonly used in applications that require lightweight, small, and quick accelerating motors such as:

- Robotics: In the field of robotics, the compact size and fast acceleration of coreless motors are leveraged for tasks necessitating swift movements.

- Medical Equipment: When it comes to medical equipment, devices like blood pumps integrate coreless motors to ensure a smooth and seamless operation.

- Aerospace: These motors are in aerospace applications due to their small size, lightweight, and quick acceleration, which makes them ideal for powering various systems in satellites and other spacecraft.

- Printing Equipment: Coreless motors are in printing equipment such as printers and copiers due to their smooth movement with minimal cogging, which makes them ideal for driving the print head and other moving parts.

- Electronic Devices: Compared to traditional motors, these coreless motors demonstrate superior efficiency as they utilize minimal power during idle periods or at no load speeds, enhancing their long-term operational efficiency.

When should You Use a Coreless Motor?

Choosing between a coreless brushed DC motor and a stepper motor hinges on specific application requirements. Coreless DC motors offer rapid responsiveness, facilitating swift changes in direction. Their ability to deliver smooth, continuous rotation makes them particularly suitable for applications where seamless motion is paramount. Additionally, their lower noise and vibration levels are advantageous in precision-sensitive applications. The simplicity of coreless DC motors can also lead to reduced initial and maintenance costs, and their lack of need for complex control electronics simplifies system integration. Thus, the decision should be driven by an evaluation of the application's or system's demands.

Coreless motors represent a pioneering approach towards compact and efficient motion control, with a multitude of inherent advantages such as enhanced efficiency, decreased weight and size, low inertia, precise motion, and reduced current draw. These attributes have facilitated their deployment across a broad array of applications, and they are expected to gain further ubiquity in the future. Whether the objective is to augment the functionality of an existing application, devise a new medical device, or implement motion control within a space-restricted scenario, coreless motors might just offer the optimal solution.