What is a Frameless Motor?

What is a Frameless Motor?

In today's world, the use of electric motors has become increasingly common in various industries. From automobiles to household appliances, electric motors play a crucial role in making our lives easier and more efficient. One of the most innovative motors that have gained traction in recent years is the frameless motor. But what exactly is a frameless motor, and how does it work?

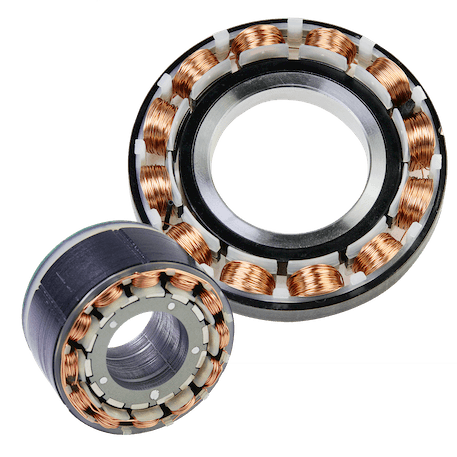

A frameless motor is a type of motor that doesn't have a traditional motor frame or housing. Instead, it consists of a rotor and a stator which are mounted directly onto the machine's structure. This unique design results in several benefits, including increased power density, improved efficiency, and reduced weight and size.

How Does a Frameless Motor Work?

So how does a frameless motor work? In a frameless motor, the stator and rotor are separate components that are mounted directly onto the machine's structure. The stator consists of a set of wound copper coils that are placed in a circular pattern, while the rotor consists of a set of permanent magnets that are arranged in a complementary pattern. When an electric current is applied to the stator, it creates a magnetic field that interacts with the rotor's permanent magnets, causing it to rotate.

Advantages of a Frameless Motor

One of the main advantages of a frameless motor is its increased power density. Because there is no housing or frame, the motor can be designed to fit into tight spaces and can provide greater thermal transfer. This means that the motor can produce more power than a traditional motor of the same size, making it ideal for applications where space and weight are critical factors.

Another benefit of frameless motors is their improved efficiency. Because frameless motors can be designed with large diameters, they can generate a lot of torque, often eliminating the need for a gearbox. Additionally, the absence of a housing further reduces the motor’s weight, allowing for even more improvement in efficiency.

The advantage of a large diameter also opens the possibility for a large hollow bore. Traditional motors consist of a solid shaft that limits the maximum possible bore size. With a frameless motor, the large bore allows the designer to integrate cabling or optics through the motor itself.

One of the most significant advantages of a frameless motor is its versatility. Because the motor can be mounted directly onto the machine's structure, it can be used in a wide range of applications, including robotics, medical devices, aerospace, and more. Additionally, the motor's design allows for customization to meet specific performance requirements, such as torque, speed, and power.

Applications of Frameless Motors

Frameless motors are used in a wide range of applications, particularly those where space and weight are at a premium. Some common applications of frameless motors include:

- Aerospace and aviation equipment, including drones and UAVs

- Medical equipment, including surgical robots and MRI machines

- Industrial automation and robotics, including pick-and-place machines and CNC machines

- Marine propulsion systems and underwater vehicles

- Electric vehicles, including hybrid and electric cars

Despite the many advantages of a frameless motor, there are also some challenges associated with this type of motor. One of the biggest challenges is the mounting process. Because the motor doesn't have a housing or frame, it needs to be mounted precisely to ensure that the rotor and stator are aligned correctly. However, to ensure the proper fit and placement, our team of engineers will work with you and your team every step of the way.

A frameless motor is a unique and versatile type of motor that has many advantages over traditional motors. Its increased power density, improved efficiency, and customizable design make it an ideal choice for many different applications. However, its lack of housing and precise mounting requirements can pose challenges for some applications. Overall, the frameless motor is an exciting development in motor technology that's sure to play a significant role in the future of many industries.