zero cogging

Zero-Tech

Zero Cogging

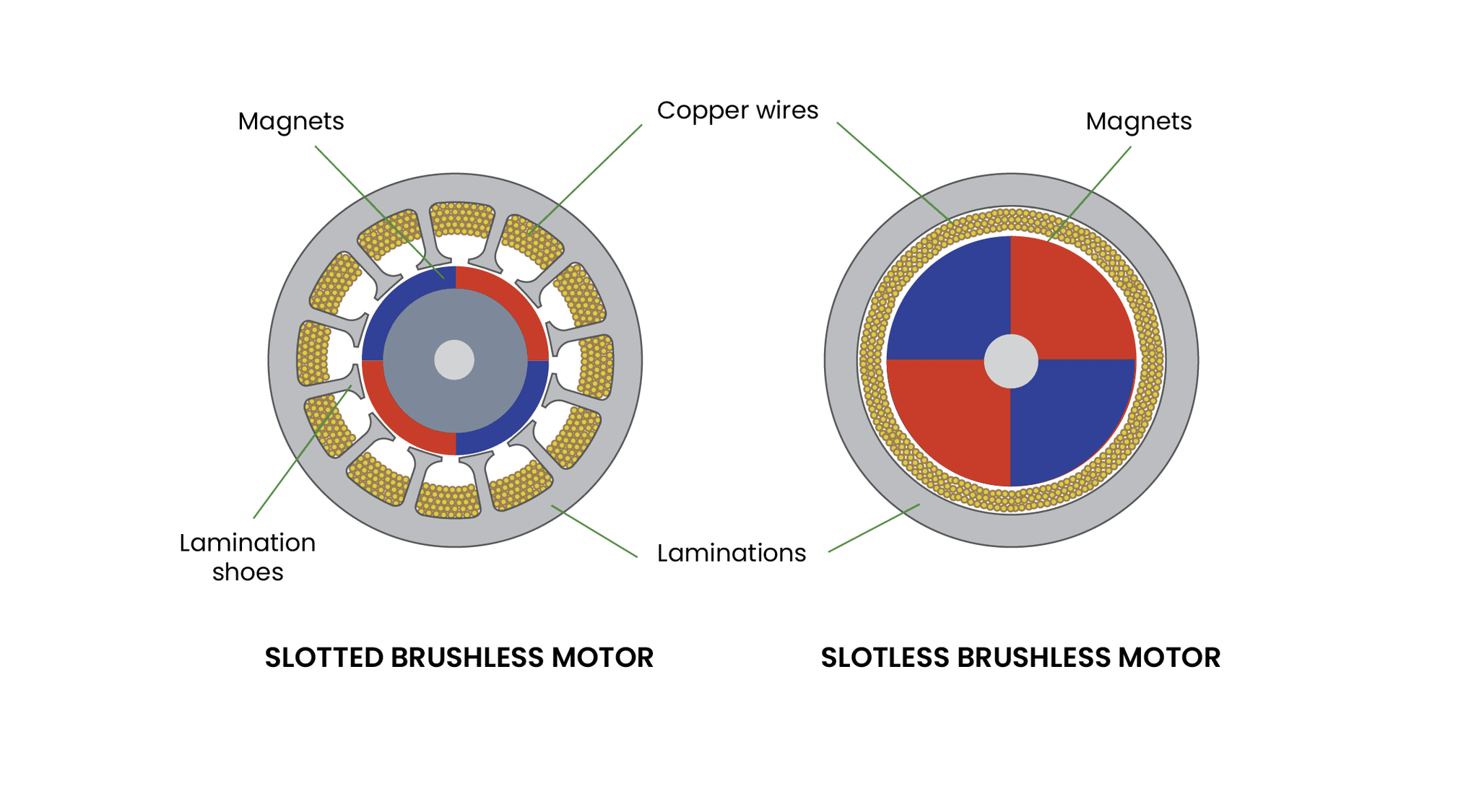

Slotless brushless DC motors reduce cogging torque by utilizing a smooth ironless rotor design instead of traditional laminated steel cores with slots, leading to a more uniform magnetic interaction between the rotor and stator. This design results in smoother operation, enhancing performance in precision applications like robotics and CNC machinery, while also improving positioning accuracy and minimizing mechanical vibrations and noise. The reduced cogging torque allows for more efficient operation, as the motor can respond readily to control inputs without compensatory measures, ultimately contributing to a longer operational lifespan due to decreased wear on components. These advantages make slotless motors ideal for applications requiring high performance, precision, and reliability.

Slotless BLDC Motors

Slotless brushless DC motors minimize cogging torque by eliminating the traditional slots found in wound stators. Instead of using a laminated steel core with distinct slots, these motors utilize a smooth ironless rotor design, which allows for continuous magnetic interaction between the rotor and stator. This design reduces the magnetic reluctance variations that typically cause cogging, resulting in a more uniform torque output throughout the rotation.

The advantages of lower cogging in brushless DC motors include:

- Smoother Operation: Reduced cogging torque leads to smoother rotational motion, enhancing performance in precision applications such as robotics and CNC machinery.

- Improved Positioning Accuracy: With less cogging, the motor can maintain more precise control over its position, making it ideal for applications requiring high accuracy, such as servo systems and automated assembly.

- Lower Vibration and Noise: The absence of cogging reduces torque ripple, which in turn minimizes mechanical vibrations and noise during operation, contributing to quieter performance in sensitive environments.

- Increased Efficiency: Lower cogging torque allows for more efficient operation, as the motor can respond more readily to control inputs without the need for compensatory measures, improving overall energy efficiency.

- Extended Lifespan: Smoother operation and reduced mechanical stress lead to less wear on components, contributing to a longer operational lifespan of the motor.

These characteristics make slotless motors particularly advantageous in applications demanding high performance, precision, and reliability.

Ready to start on your next product development project?