space

Space flight is challenging enough without having to worry about the operational limitations of the components used in the devices going into orbit. And since motors are a major component used in any motion system, specifications need to be on-target and reliable over a long period of time.

- AS9100D Certified

- Flight Tested and Proven

- Vibration Management

- Temperature Management

- Optimized Power Consumption

- Low Outgassing & Contamination

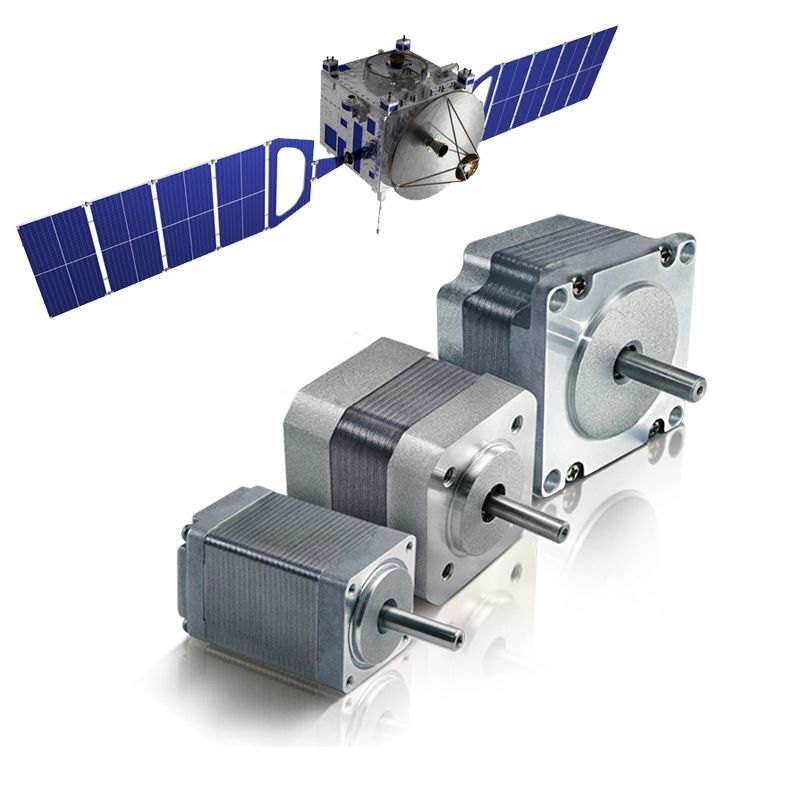

- COTS Space/Vacuum Grade Motors

- US Based Support & Manufacturing

The harsh environment of vacuum and microgravity applications pose many issues with component capabilities that don’t commonly have to be dealt with here on Earth. That is especially true when it comes to components where movement is their primary function—such as motion control systems. Motors specifically introduce many inherent problems to the environment, mainly due to the fact that they require considerable amounts of power to operate, can generate excessive heat, can introduce unwanted vibrations into the system, and can become a source of contaminants.

Lin Engineering Space grade motors are flight-proven to deal with these problems.

Why Partner With Lin Engineering?

We are a “Solution First” company that not only supplies the motors that you need, but also provides the Engineering expertise needed to find, optimize, and customize the right motors that will perform within your space system optimally and reliably.

US Based Manufacturing And Support

Our office in Morgan Hill, California hosts one of our manufacturing floors as well as our engineering team. This allows our engineering team to provide support for any questions that may arise during the process. A big advantage of having our engineers near the production floor is that they can quickly review prototypes to ensure they are accurate to the specifications. Having US based manufacturing means Lin Engineering can provide quick responses to spikes in orders as well as kanban stocking.

Applications Support

Our US based engineering team is excited to help solve your motion control problems or issues. Our engineers have helped solve motion control issues for a wide array of industries as well as helped companies design and build new products. Being exposed to so many different projects has helped our team to think outside of the box when looking for a solution.

Engineering Support

For OEM Motor Projects, we’ll work directly with your engineering team throughout the design phase of your project to ensure the best overall system optimization and motor fit while avoiding over-engineering. Our experienced engineers can help you eliminate costly complexities and over-designing while keeping in mind future developments and improvements.

Fast Prototyping

Here at Lin Engineering we understand keeping your project progressing is important; that’s why we offer quick prototyping turnaround times, as quick as 7 days. This is possible due to the modular design of our motors. Don’t get caught waiting for the parts you need, using our rapid prototyping tool you can customize and order the motors you need fast.

Motors Capable of Withstanding Extreme Enviroments

Vacuum Rated Motors

IP Rated Motors

Hot & Cold Motors

These motors are designed and manufactured to operate in unique environments for specific applications. Vacuum-rated motors, for example, are necessary for environments where out-gassing needs to be minimized such as vacuum chambers, space applications, and clean room environments. IP (Ingress Protection) rated motors are perfect for applications exposed to humidity, water, oil, and other various debris. We also carry motors that are specifically designed to operate in extreme hot and cold temperatures.

- Vacuum and Ultra High Vacuum Grade Motors

- Ingress Protection (IP) Rated Motors

- Hot/Cold Temperature Operating Motors