Customize winding of Hybrid Stepper Motors to achieve higher efficiency

Customize winding of a Hybrid Stepper Motor to achieve higher efficiency.

There are plenty of modifications we can make to a Hybrid Stepper Motor to optimize the motor’s performance to your specific application, and one of those modifications is customizing the motor’s windings.

A hybrid stepper motor is an electromagnetic device that consists of two main components: the stator and the rotor. Hybrid Stepper Motors incorporate a permanent magnet on the rotor side, while the stator side is spooled with coils of copper wire (magnet wire). When coils are energized, a magnetic field is generated, which either attracts or repels the magnets embedded in the rotor. This creates motion.

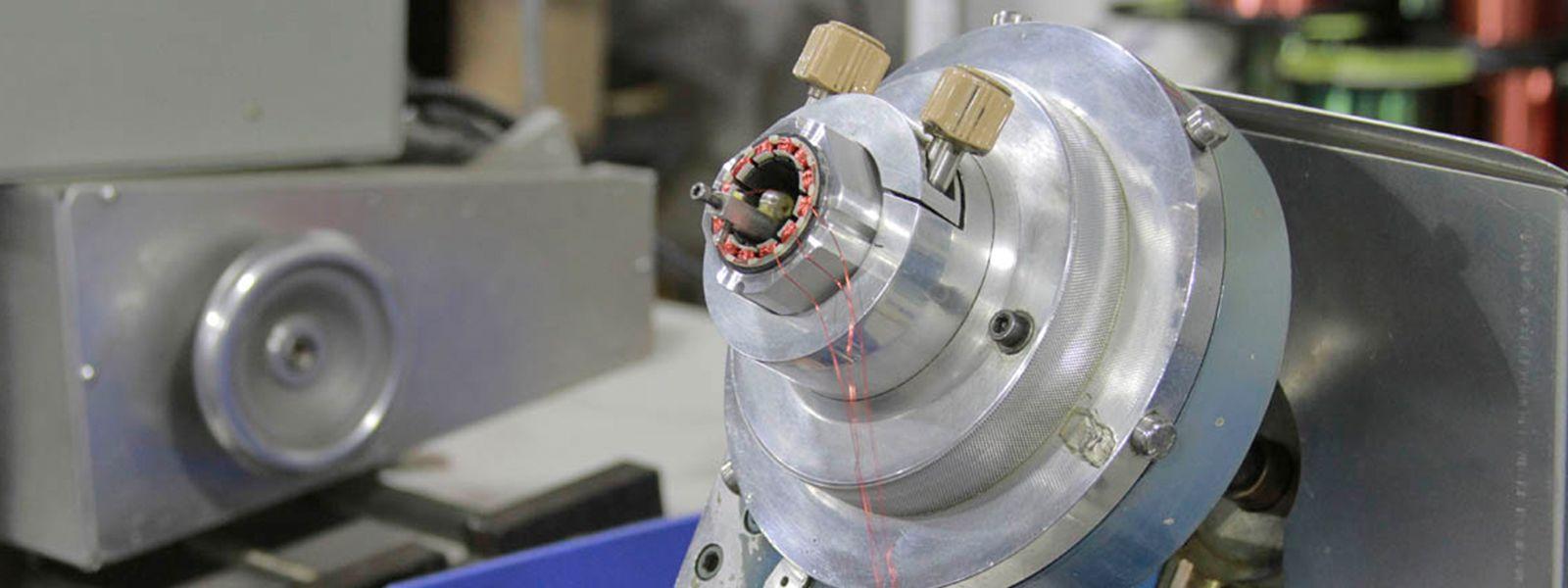

When winding the stator, there are many variables that will affect the performance characteristics of the motor. Things like gauge of the wire, the thickness of the wire insulation, number of turns per coil, the tension of the magnet wire, along with other things will impact the motor’s performance characteristics.

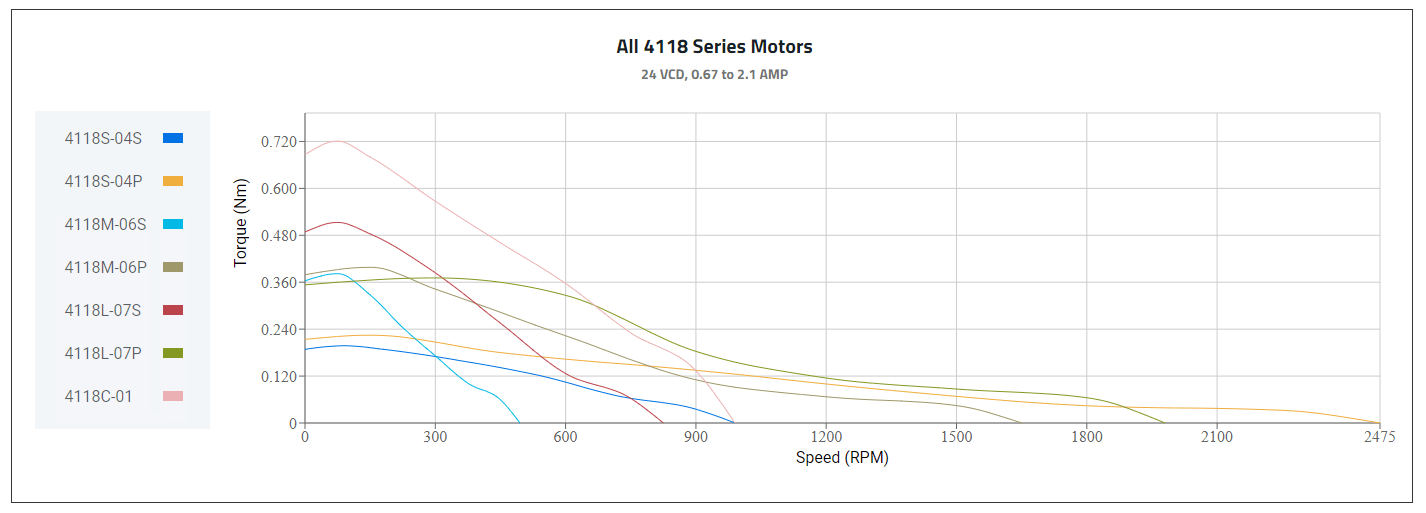

The exact winding recipe will affect the amount of the current that can be applied to the motor, the rate of charge and discharge per pole, the strengths of the magnetic flux, and so on. This is why we can have many motors of the same stack length, using the same stator and rotor components, but with large variations in performance. Winding dictates the amount of torque and speed the motor can achieve.

The performance of each motor can be represented as a torque curve. Some motors are capable of higher torque but at lower maximum speeds, while another motor can achieve higher maximum speeds with lower maximum torque.

Most applications will operate within a specific speed and torque range. Sometimes you can get lucky and find a “cataloged” motor that will work optimally within your specific application parameters, but more often than not, there’s room for improvement.

There are many scenarios where you may want to optimize the motor’s performance. For instance, you may want to increase a motor’s torque at a specific speed range, or increase its speed at a specific torque range, or decrease power consumption at a specific torque and speed range.

Additionally, like all electromagnetic devices, each motor will have a natural point of resonance, which can introduce unwanted vibrations into the system. If your speed requirement conflicts with this natural point of resonance, then customizing the windings can shift, or redistribute the point of resonance, so it does not interfere with the target operating range of the motor.

By manipulating the winding recipe, i.e. changing the gauge of the wire, the number of turns per coil, wire tension, and so on, we can often hit the specific torque and speed targets required for your specific needs. Of course, if the laws of physics allow it.

For OEM-type projects, our Application Engineering team can work directly with your engineering team to optimize the motor for your specific needs. Our database consists of thousands of different winding recipes that we’ve tested in the past. We can look at the specific performance characteristics of your application and often match a winding that will perform optimally. If we cannot find a winding, we can always design and test a series of windings to nail down a recipe that will work for you.

Our engineering team is based in Northern California at the manufacturing facility. Meaning that they have access to the winding machines and testing equipment needed to assemble and test most hybrid stepper motors in real-time. This can drastically speed up the prototyping and validation process, as we can often skip on sending sample requests to off-site facilities, which can take days or weeks.

If you’re designing a new product or iterating an existing design, and need OEM hybrid stepper motors that are customized and optimized for your specific application, then reach out to us and we’ll work directly with your team to nail down a motor that works perfectly.

News

Continue Reading

Methods for Increasing Accuracy in Stepper Motors

Stepper motors are used in a variety of applications and in a wide spectrum of industries as a cost-effective way to provide motion for everything from robots to medical devices and from conveyors to machine tools. This article explores the ways in which an engineer can provide greater accuracy from the motor when it becomes a critical requirement.

The Advantages of Slotless Motors Over Standard BLDC Motors

Slotless motors have gone through innovations in design as well as manufacturing, making them a good choice for specific applications. This article will explore the benefits and drawbacks of slotless motors and provide information that may help in knowing when to and when not to select them as a solution.