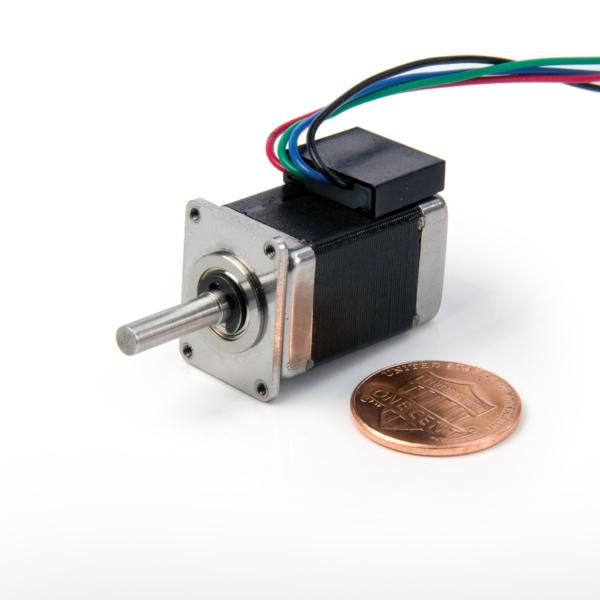

106 Series106-13-01Hybrid Stepper Motor

- NEMA 06 (0.630 in) Frame Size

- 3.46° Step Angle

- 1.300 in Length

- 1.98 oz-in Holding Torque

Unit Price:

$76.52

Inventory:

10 Available in 2 Business Days

Ships:

2 Business Days

Part Number:

106-13-01

Rapid Prototyping Motors

Start prototyping your next product fast. Our rapid prototyping motors provide a fast and convenient way for you to start prototyping your next product or design iteration with minimum downtime. Rapid prototyping motors are customizable and usually ship within 2-5 business days of ordering.

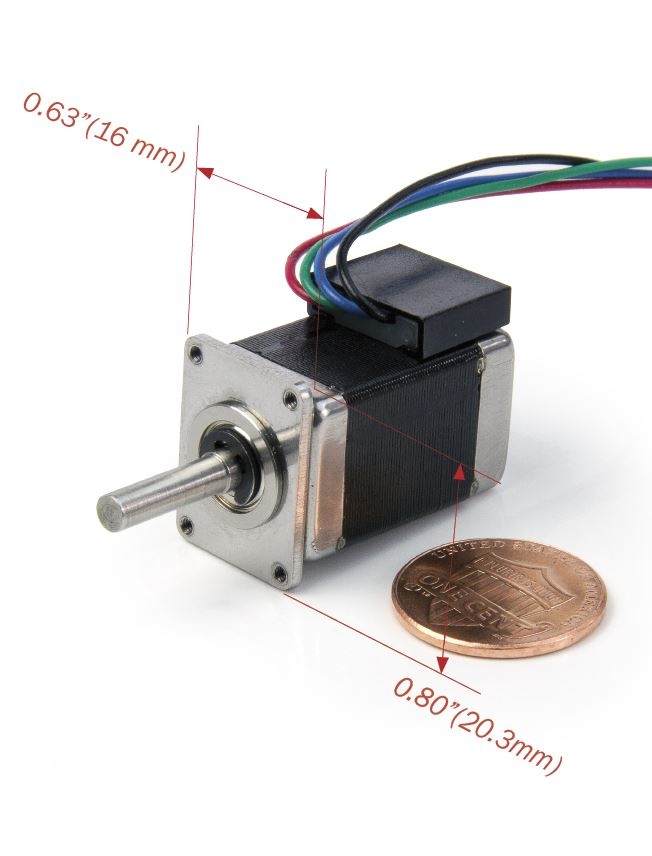

Dimensions

| Model | DIM. A (length) in |

|---|---|

| 106-13-01 | 1.300 in |

Torque Curves

Speed

Find the motor that fits your Target Torque (oz-in) and Target Speed (RPM)

Motor Specifications

| Base Motor Part Number | 106-13-01 |

| Step Angle | 3.46° |

| Frame Size | 0.630 in |

| NEMA Size | NEMA 06 |

| Body Length | 1.300 in |

| Current (AMP) | 0.6 AMP |

| Holding Torque | 1.98 oz-in |

| Resistance | 6.58 ohm |

| Rotor Inertia | 0.009 oz-in² |

| Number of leads | 4 |

| Connection | Bipolar |

| Weight | 0.101 lbs |

Operating Specifications

| Radial Play | 0.001 in @ 1 lbs |

| End Play | 0.003 in @ 3 lbs |

| Shaft Run Out | 0.002 TIR |

| Concentricity of Mounting Pilot to Shaft | 0.003 TIR |

| Perpendicularity of Mounting Pilot to Face | 0.003 TIR |

| Max Radial Load at Dimension "K" from mounting face | 4.5 lbs |

| Dimension "K" | 0.500 in |

| Max Axial Load | 0.45 lbs |

| Maximum Case Temperature | 176.00 °F maximum |

| Ambient Temperature | -4 °F to 122.00 °F |

| Storage Temperature | -4 °F to 212.00 °F |

| Humidity Range (%) | 85% or less, non-condensing |

| Magnet Wire Insulation | Class B 130 deg C |

| Insulation Resistance | 100M Ohm at 500 VDC |

| Dielectric Strength | 500 VDC for 1 min |

Features and Benefits

One of the biggest problems Engineers face while designing ever-smaller devices is making things move. As the size of equipment decreases, the demand for smaller motors increase. However, oftentimes small enough motors simply don’t exist, and if they do, they do not provide enough torque or speed to be useful in the application. Often, the only option is to use a large framed motor and shrink everything else around it. Motion control is the real bottleneck which forces Engineers to compromise on the footprint of their device.

Our new 106 Hybrid Stepper Motor is what many Engineers have been waiting for. It solves many of the problems in motion control which prevented equipment from getting smaller.

By applying our experience and our Engineering know-how in the field of Hybrid Stepper Motor technology, we were able to succeed where many have failed. We’ve successfully created a NEMA 6 sized stepper motor that delivers plenty of performance. The 106 outperforms all other motors of similar size on nearly all metrics: it delivers more torque at higher speeds with greater accuracy.

The 106 measures just 16mm in width, making it one of the smallest Hybrid Stepper Motors on the market today. The NEMA 6 frame size means that the 106 Hybrid Stepper Motor can be designed into challenging spots with minimal allotted space. Spots where conventional hybrid stepper motors could not previously fit. This opens up a far broader Engineering flexibility and the ability to design much smaller equipment.

By increasing the step angle from a typical 1.8 degree to 3.46 degree, we are able to achieve nearly twice as much holding torque as closest competing design, and nearly four times more holding torque than a conventional permanent magnet (PM) stepper motor of similar size (which usually top-out at only 0.5 oz-in of holding torque).

A typical PM motor may only deliver 20 steps per revolution, or a step angle of 18 degrees. In comparison, our 3.46 degree motor delivers 5.7 times higher resolution than a typical PM motor. High resolution translates to higher precision. The 106 offers all of the benefits of a hybrid stepper, and none of the drawbacks of a PM motor.

The 106 can deliver similar speed performance of a BLDC motor. By combining the 3.46 degree step angle with our low inertia rotor design, we are able to achieve over 1 oz-in of dynamic torque at 8000 RPM.

Applications

The 106 is a perfect candidate for many applications that require tiny motors, especially in the field of medical devices and laboratory automation. Applications that require high degree of precision like miniature pumps, fluid metering and control, and optical sensor controls can take advantage of the 106 motor. The 106 can even be incorporated into motorized hand tools like electronic pipettes, and other handheld devices where Hybrid Stepper Motors were previously impossible to integrate.

Handheld Tools

Flow Control Valves

Optical/Aperture Control

Miniature Pumps

Downloads

Get the motor you need

Just fill out a Request for a Quote form, and tell us about your application and your needs. One of our applications specialists will review your request, and provide you with a quote promptly.