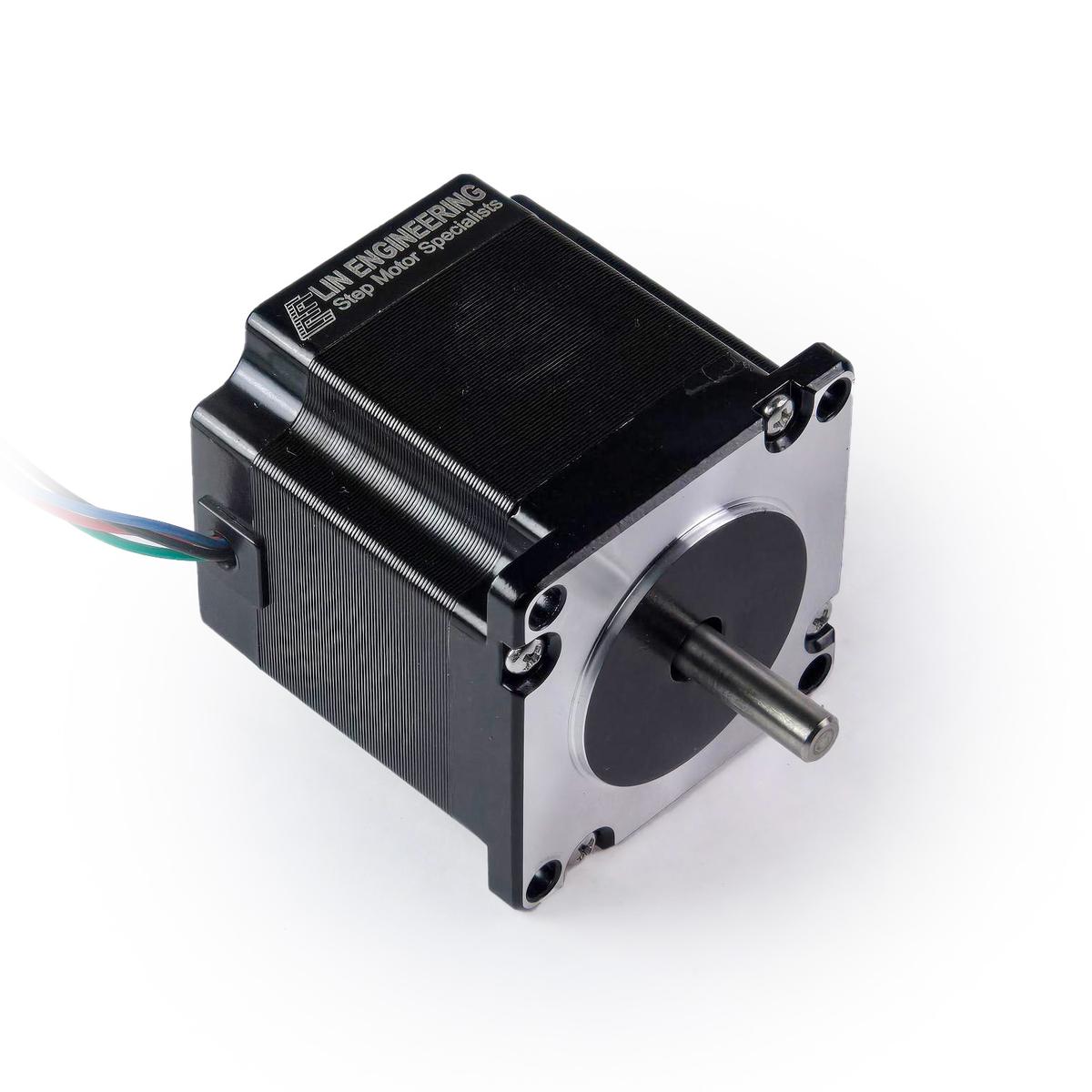

G5709 SeriesHybrid Stepper Motor

- High Resolution

- High Step Accuracy

- NEMA 23 (2.250 in) Frame Size

- 0.9° Step Angle

- 1.74 to 3.08 in Length

- 83.55 to 270.48 oz-in Holding Torque

Models

| Model # | NEMA size | Frame size | Step Angle | Connection Type | Length, in | Current AMP | Holding Torque, oz-in | Resistance | Inertia, oz-in² | Weight, lbs | # of Leads | Availability | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G5709L-01P | NEMA 23 | 2.250 in | 0.9° | Parallel | 3.080 in | 2.8 AMP | 270.48 oz-in | 1.44 | 2.6 oz-in² | 2.601 lbs | 4 | Legacy |

| G5709L-01S | NEMA 23 | 2.250 in | 0.9° | Series | 3.080 in | 1.4 AMP | 270.48 oz-in | 0.59 | 2.6 oz-in² | 2.601 lbs | 4 | Legacy |

| G5709L-08 | NEMA 23 | 2.250 in | 0.9° | Bipolar | 3.080 in | 1.44 AMP | 270.48 oz-in | 5.42 | 2.6 oz-in² | 2.601 lbs | 4 | Legacy |

| G5709M-02P | NEMA 23 | 2.250 in | 0.9° | Parallel | 2.200 in | 4.2 AMP | 168.52 oz-in | 0.61 | 1.5 oz-in² | 1.501 lbs | 4 | Legacy |

| G5709M-02S | NEMA 23 | 2.250 in | 0.9° | Series | 2.200 in | 2.1 AMP | 168.52 oz-in | 2.53 | 1.5 oz-in² | 1.501 lbs | 4 | Legacy |

| G5709X-01P | NEMA 23 | 2.250 in | 0.9° | Parallel | 1.740 in | 2.8 AMP | 83.55 oz-in | 1.07 | 0.7 oz-in² | 1.052 lbs | 4 | Legacy |

| G5709X-01S | NEMA 23 | 2.250 in | 0.9° | Series | 1.740 in | 1.4 AMP | 83.55 oz-in | 4.3 | 0.7 oz-in² | 1.052 lbs | 4 | Legacy |

| G5709X-15P | NEMA 23 | 2.250 in | 0.9° | Parallel | 1.740 in | 4.2 AMP | 83.55 oz-in | 0.47 | 0.7 oz-in² | 1.052 lbs | 4 | Legacy |

| G5709X-15S | NEMA 23 | 2.250 in | 0.9° | Series | 1.740 in | 2.1 AMP | 83.55 oz-in | 1.89 | 0.7 oz-in² | 1.052 lbs | 4 | Legacy |

Torque Curves

Speed

- G5709L-01P

- G5709L-01S

- G5709M-02P

- G5709M-02S

- G5709X-01P

- G5709X-01S

Find the motor that fits your Target Torque (oz-in) and Target Speed (RPM)

Dimensions

| Model | DIM. A (length) in MAX |

|---|---|

| G5709L-01P | 3.080 in |

| G5709L-01S | 3.080 in |

| G5709L-08 | 3.080 in |

| G5709M-02P | 2.200 in |

| G5709M-02S | 2.200 in |

| G5709X-01P | 1.740 in |

| G5709X-01S | 1.740 in |

| G5709X-15P | 1.740 in |

| G5709X-15S | 1.740 in |

Operating Specifications

| Radial Play | 0.001 in @ 1 lbs |

| End Play | 0.003 in @ 3 lbs |

| Shaft Run Out | 0.002 TIR |

| Concentricity of Mounting Pilot to Shaft | 0.003 TIR |

| Perpendicularity of Mounting Pilot to Face | 0.003 TIR |

| Max Radial Load at Dimension "K" from mounting face | 15 lbs |

| Dimension "K" | 0.550 in |

| Max Axial Load | 13 lbs |

| Maximum Case Temperature | 176.00 °F maximum |

| Ambient Temperature | -4 °F to 122.00 °F |

| Storage Temperature | -4 °F to 212.00 °F |

| Humidity Range (%) | 85% or less, non-condensing |

| Magnet Wire Insulation | Class B 130 deg C |

| Insulation Resistance | 100M Ohm at 500 VDC |

| Dielectric Strength | 500 VDC for 1 min |

Legacy Product

While groundbreaking in performance and efficiency, this product is considered a Legacy Products. These motors were designed with a deep understanding of customer needs, powering advancements in robotics and automation through tailored solutions. These innovative products laid the foundation for our continued success, inspiring the development of our latest frameless and slotless motors. Lin Engineering remains committed to delivering cutting-edge solutions, staying true to the principles that drove the success of our legacy motors.

Customizations & Optimizations

Lin Engineering can ensure that your hybrid stepper motor is optimized to deliver the required performance for your specific application, whether it’s increasing torque at a specific speed range, reducing noise or vibration, or optimizing for minimal power consumption, or making specific modification to ensure proper and native fit within your assembly.

Customization Services Include:

- Optimized Winding

- Multiple Shaft Options

- Customized Leads & Connectors

- Customized Housings & Mountings

- Bearings & Lubricants

- Mechatronic Solutions

- Environmental Protection

- Drivers & Controllers, Encoders, Gearboxes & Accessories

The result is that you’ll get a motor that is fully optimized for your specific applications and configured to seamlessly fit with your assembly. This reduces your product's complexity, and increases the speed and ease of the assembly of your final product.

Speak with one of our sales representatives about your specific application needs by filling out a request for a quote.